The Power of the Lincoln MIG 210: Revolutionizing Welding

The world of welding has seen remarkable advancements in technology, and the Lincoln MIG 210 stands out as a prime example of innovation meeting performance. For both professionals and hobbyists in the welding industry, selecting the right equipment is crucial. This article provides an in-depth look at the Lincoln MIG 210, exploring its features, benefits, and overall significance in modern welding practices.

1. Introduction to the Lincoln MIG 210

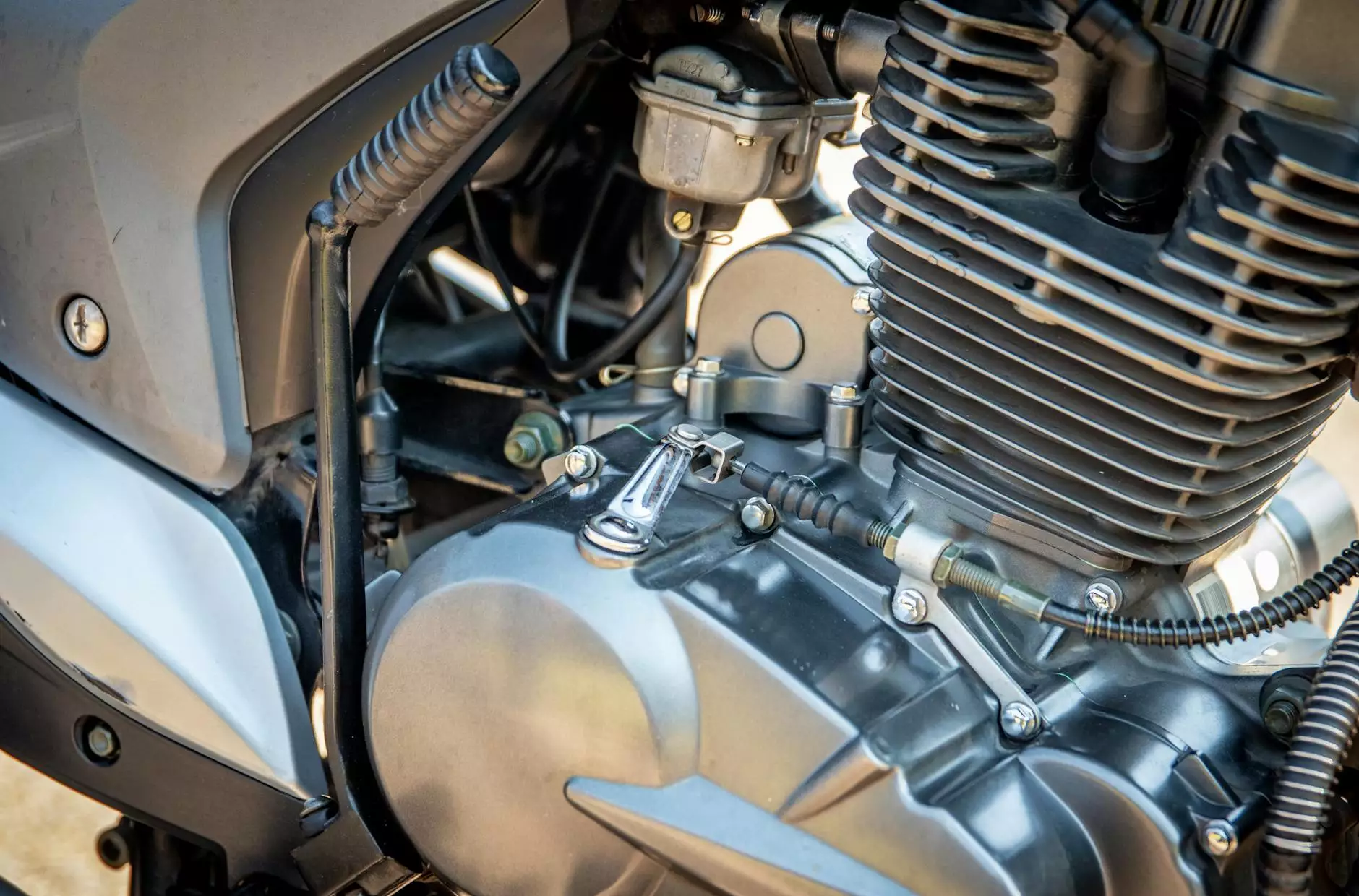

The Lincoln MIG 210 is a multifunctional MIG welder that offers exceptional flexibility and user-friendly operation. Designed for both home users and professionals, this machine is capable of handling a wide range of welding tasks. From automotive repairs to light industrial usage, its versatility makes it a top choice in the cutting and welding equipment market.

2. Key Features of the Lincoln MIG 210

Understanding the features of the Lincoln MIG 210 is essential when considering its application in welding projects. Below are some of the standout features:

- Superior Welding Technology: The machine uses advanced MIG technology that allows for smooth and stable arcs, providing a clean weld.

- Multi-Process Capability: Be it MIG, TIG, or stick welding, the Lincoln MIG 210 can handle various processes, making it an all-in-one solution.

- Adjustable Output Settings: Users can easily adjust the voltage and wire feed speed, allowing for customizable welding that suits different materials.

- Portability: Weighing only around 38 pounds, this welder is highly portable, meaning it can be taken to job sites with ease.

- User-Friendly Interface: With clear indicators and controls, both beginners and seasoned welders can operate it without hassle.

- Durability and Reliability: Built with high-quality materials, the Lincoln MIG 210 is designed to withstand heavy usage and varied environmental conditions.

3. Benefits of Using the Lincoln MIG 210

Choosing the Lincoln MIG 210 for your welding needs comes with a range of benefits that can streamline your projects:

3.1 Enhanced Precision in Welding

The precision offered by the Lincoln MIG 210 is unmatched. Thanks to its stable arc and adjustable settings, welders can achieve fine and accurate welds. This is particularly beneficial in intricate projects where detail is essential.

3.2 Versatility in Applications

From welding thin sheets of metal to thicker plates, the Lincoln MIG 210 can accommodate a wide variety of materials and thicknesses, making it suitable for multiple applications including:

- Automotive repairs.

- Home improvement projects.

- Metal art creation.

- Heavy fabrication work.

3.3 Cost-Effectiveness

Investing in the Lincoln MIG 210 translates to long-term cost savings. Its durability means fewer repairs and replacements. Additionally, the machine's efficiency helps in reducing waste during projects, further lowering costs.

4. The Importance of Understanding Welding Techniques

While the Lincoln MIG 210 simplifies the welding process, understanding basic welding techniques remains vital:

- Preparing the Work Area: Cleaning the surfaces to be welded is crucial for a good bond.

- Choosing the Right Filler Material: The choice of the filler material depends on the base metals used and the welding process.

- Maintaining Proper Travel Speed: Control over travel speed influences the quality of the weld.

5. Testimonials and Real-World Uses

The popularity of the Lincoln MIG 210 is evident from numerous positive testimonials from users:

“The Lincoln MIG 210 has transformed my welding projects. I can switch between processes effortlessly, and the results are always top-notch!” – John D.

“As a hobbyist, I appreciate how easy it is to use the Lincoln MIG 210. It's lightweight and versatile – just perfect for my needs!” – Emily L.

6. Maintenance Tips for the Lincoln MIG 210

To ensure longevity and performance, regular maintenance of the Lincoln MIG 210 is essential:

6.1 Regular Cleaning

Routine cleaning of the welder helps prevent buildup of dirt and contaminants which can affect performance. Make sure to clear the internal components and the power leads.

6.2 Inspect for Damage

Before starting any project, inspect the machine, especially the cables and connectors, for any signs of wear or damage.

6.3 Proper Storage

Store the welder in a dry, safe place, away from extreme temperatures or moisture to avoid corrosion.

7. Where to Buy the Lincoln MIG 210

If you're ready to elevate your welding experience with the Lincoln MIG 210, it’s important to purchase through reliable sources. Quality distributors ensure you receive genuine equipment:

- Tienda Guve: Your optimal destination for cutting and welding equipment, providing detailed product descriptions and excellent customer support.

- Online Retailers: Websites like Amazon and specialized welding shops often have competitive prices and customer reviews.

- Local Hardware Stores: Check for brick-and-mortar options that may offer real-time inventory and personal assistance.

8. Conclusion: The Future of Welding with the Lincoln MIG 210

The Lincoln MIG 210 is much more than just a welding machine; it is a crucial investment that enhances your capabilities in the welding industry. With its blend of user-friendliness, versatility, and advanced technology, it opens up a world of possibilities for both professional welders and DIY enthusiasts alike.

By choosing the Lincoln MIG 210, users can ensure they have a reliable partner in welding that not only meets but exceeds their expectations. As technology continues to evolve, the Lincoln MIG 210 embodies the robust standards of modern welding machinery—making it a worthy addition to any workspace.